Marc-M

Well-Known Member

As you regulars will know - I’m in the heat of getting my engine done – as I have been hitting the forum for all sorts of help...

I have found a company who will restore my head – but it will need milling flat after welding work

My engine builder is asking if we can get a Vernier Pulley as the timing will be slightly off and as we will be running it on the dyno first, he wants to get it perfect.

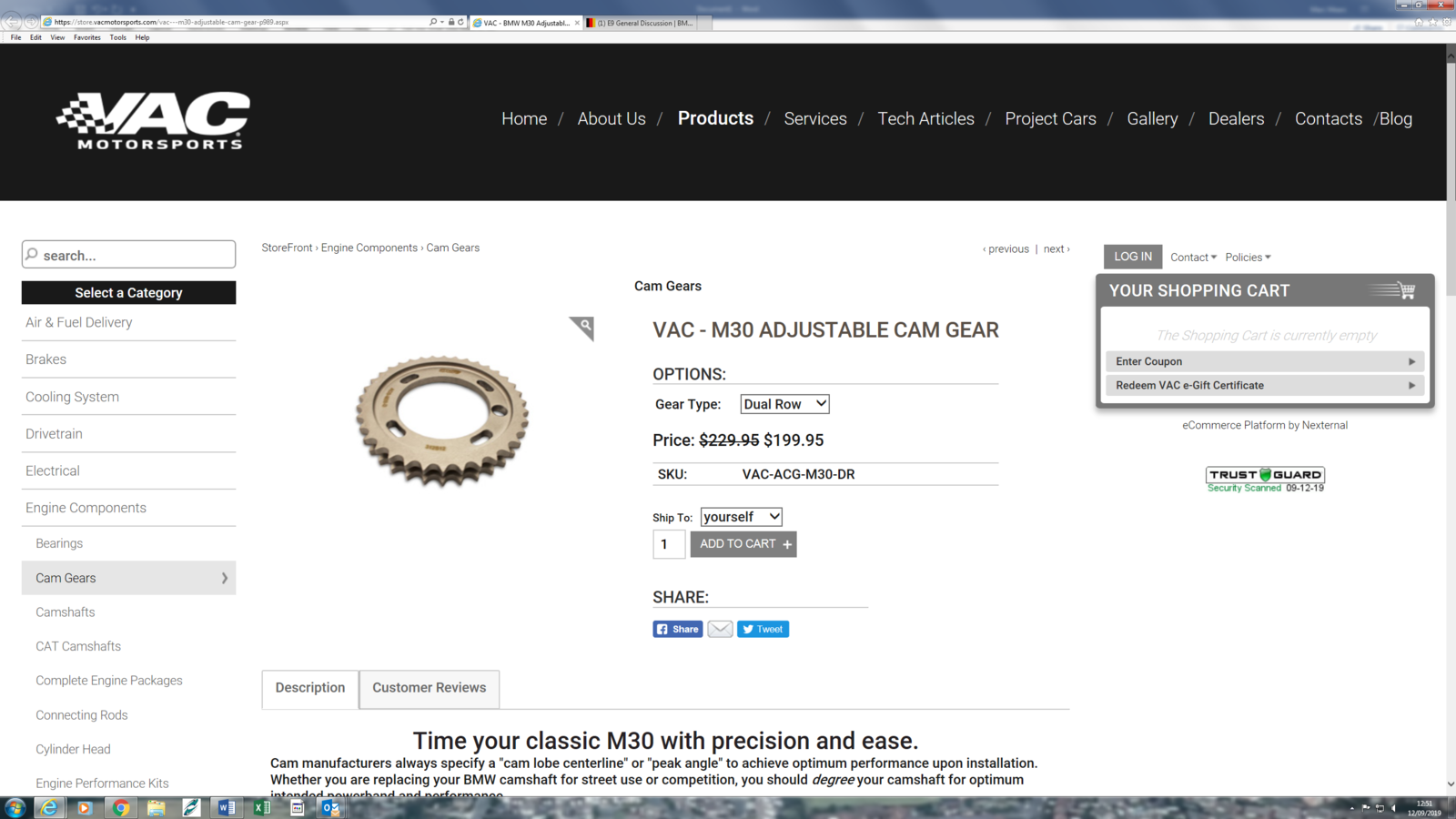

I have had a quick look and have found these guys…

Has anyone used them or is there anyone else out there ?? in Europe??

Thanks

Marc

I have found a company who will restore my head – but it will need milling flat after welding work

My engine builder is asking if we can get a Vernier Pulley as the timing will be slightly off and as we will be running it on the dyno first, he wants to get it perfect.

I have had a quick look and have found these guys…

Has anyone used them or is there anyone else out there ?? in Europe??

Thanks

Marc