Hi there !

After a quick presentation (https://e9coupe.com/forum/threads/new-member-e9-3-0-csi.45031/), here is the thread for the restoration of my E9 3.0CSi from 1972. I do not have a lot of history about this car except that it was stopped in 1983 and bought in 2015 by the previous owner for a restoration project (which was aborted). Car has been almost completely dismantled a few years ago and this is how I bought the car.

The risk of buying a dismantled car is not minor. This is a bit crazy but I believe this car was worth it. The good point is that it was possible to see and inspect the body. It is not in great condition, but this seems manageable.

I have spent the last few months sorting, identifying, and cleaning all the dismantled parts (engine, interior and exterior trims). God, there are a lot of parts!

The CS part manual was very useful and a great help. As I did not find the manual very practical to use for my case, I reported the manual into a spreadsheet. It recaps all the Euro CSi parts pre 1973 for ease of reference and follow-up.

Now that I am clear on what I have and what I am missing, I will start working on the body.

A lot of talking, now the pictures!

Car being towed on the truck. A van was needed to collect all the parts. That was such a long day that I forgot to take a picture of the big Tetris!

The car at home!

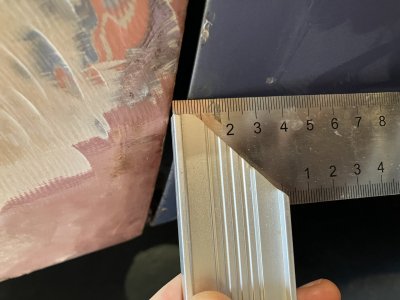

The sill and front fender are a bit rusty... No surprise!

After a quick presentation (https://e9coupe.com/forum/threads/new-member-e9-3-0-csi.45031/), here is the thread for the restoration of my E9 3.0CSi from 1972. I do not have a lot of history about this car except that it was stopped in 1983 and bought in 2015 by the previous owner for a restoration project (which was aborted). Car has been almost completely dismantled a few years ago and this is how I bought the car.

The risk of buying a dismantled car is not minor. This is a bit crazy but I believe this car was worth it. The good point is that it was possible to see and inspect the body. It is not in great condition, but this seems manageable.

I have spent the last few months sorting, identifying, and cleaning all the dismantled parts (engine, interior and exterior trims). God, there are a lot of parts!

The CS part manual was very useful and a great help. As I did not find the manual very practical to use for my case, I reported the manual into a spreadsheet. It recaps all the Euro CSi parts pre 1973 for ease of reference and follow-up.

Now that I am clear on what I have and what I am missing, I will start working on the body.

A lot of talking, now the pictures!

Car being towed on the truck. A van was needed to collect all the parts. That was such a long day that I forgot to take a picture of the big Tetris!

The car at home!

The sill and front fender are a bit rusty... No surprise!