You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need advice. how to check compression, procedure details

- Thread starter deQuincey

- Start date

Paper graph paper?! Very cool..

Jesus,

You always take it up a notch, and do it in style! Very cool find. I don't know that I'd use it for testing the compression, but I am jealous from a cool vintage tool perspective.

Jesus,

You always take it up a notch, and do it in style! Very cool find. I don't know that I'd use it for testing the compression, but I am jealous from a cool vintage tool perspective.

i was after one of this for a while, now the time has come, i tried yesterday only to see that i can use it in all the spark positions, as number six is very tight fit, but it worked reasonalbly well, alternative it was to buy an accesory tube

i still have some things to do before doing this but i promise to bring here the results

for compression testing, you want to get as much air flowing (and compressing) as possible, so keep the throttle wide open so the "suck" is not just drawing a vacuum. I keep turning the engine until the needle on the gauge is stable(ish). Important to be consistent with this on all 6 cylinders. I also remove all the plugs before I start, partly to enable the engine to spin faster on the starter, and partly as it's easier, especially as I'll probably repeat the test at least once. As you progress, the battery may get a bit flat, so be alert to the sound of the starter as you go

for leak-down testing, I have built a DIY tester from some air tool valves, lines, etc. The orifice plate is a 1mm hole drilled through an epoxy filled connector. I've always managed to balance the piston at TDC when doing this. It doesn't work every time, but I have a 360 degree protractor which I fix on the vibration damper to allow a degree of accuracy when setting to TDC. To build the fitting that screws into the spark-plug holes I smashed the ceramic centre out of a spark plug and glued some compressed air line through the metal part. I built this tester kit when a top-end rebuild on my E24 took a wrong turn and the rings got gummed up with carbon the deposits I'd scraped off the piston crowns (whilst I was there...). The leak down test clearly diagnosed poor ring sealing, which was then fixed with a slug of ATF in each plug hole.

thank you Drew

i am prepared to do this:

"for compression testing, you want to get as much air flowing (and compressing) as possible, so keep the throttle wide open so the "suck" is not just drawing a vacuum. I keep turning the engine until the needle on the gauge is stable(ish). Important to be consistent with this on all 6 cylinders. I also remove all the plugs before I start, partly to enable the engine to spin faster on the starter, and partly as it's easier, especially as I'll probably repeat the test at least once. As you progress, the battery may get a bit flat, so be alert to the sound of the starter as you go "

question now is how to prepare the rest of it

1- engine should be warm

2- plugs removed

3- coil terminal 15 removed and taped to protect derivations

4- fuel line to carbs capped

5- turn engine to remove deposits

6- start the test

please: do you see any inconsistence here ?

Last edited:

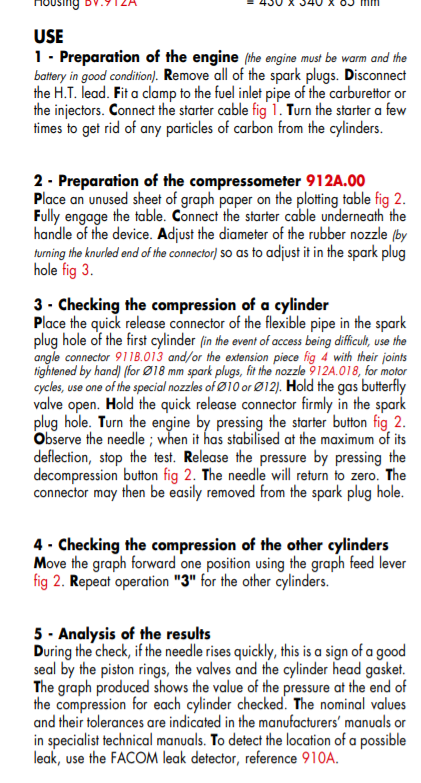

complementing info from facom testing equipment instructions

Yes, sounds fine

I was just checking the pins under the orange cover on my car, I only have pins 1,2,3,7,8 & 9, and none is connected to the stater solenoid so far as I could tell. It's possible to apply 12v (fused of course!!) to the starter solenoid directly, which means neither the fuel system or the ignition will be operated (as they would be by using the ignition key normally). Just make sure gearbox is in neutral...

Taking the plugs out of a hot m30 is: hot

I was just checking the pins under the orange cover on my car, I only have pins 1,2,3,7,8 & 9, and none is connected to the stater solenoid so far as I could tell. It's possible to apply 12v (fused of course!!) to the starter solenoid directly, which means neither the fuel system or the ignition will be operated (as they would be by using the ignition key normally). Just make sure gearbox is in neutral...

Taking the plugs out of a hot m30 is: hot