Post #10Aren’t the nuts to be on the flangers side?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M5 Guibo fail

- Thread starter BarryG

- Start date

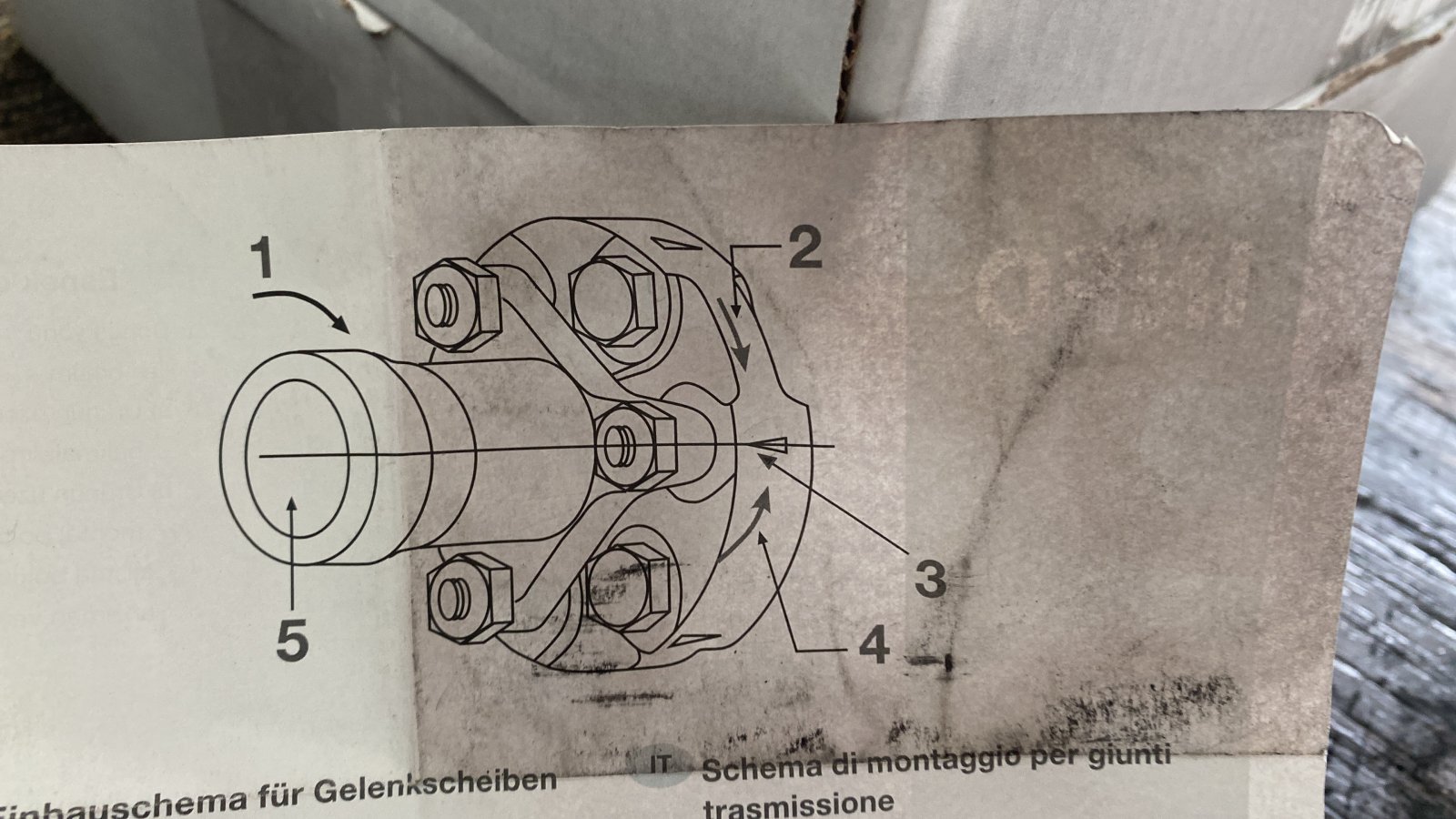

The whole point of the points (arrows) is for the tranny to be pushing or driving the thick part of the guibo.

Hi Gentlemen

I’m preparing to swap my 265 for a better 265 and discovered my Guibo going bad.

It’s a e34 m5 guibo

Probably under 5000 miles on it, maybe more

Looking up numbers I found a few,

26112226527 I want a good one ... Jurid? The best per past posts.

View attachment 74668

Help me out I don’t want to buy junk parts

Thanks

Without additional images of the giubo, I would not be so quick to condemn it as "going bad." (I have yet to see a giubo "going good") Per Andrew's observation, rag joints are the so-called weak link in the drive train and designed to absorb repeated shock, loads and naturally-occurring abuse.

If the pictured rag joint is reinforced, as I suspect it is, your joint is far from being at the end of its lifespan, despite the cracks. I know of one daily driver that has been nursing a similar looking giubo for the past two decades, and as best the owner (not me) can tell, the cracking is superficial, i.e., shallow. Unlike the non-reinforced solid rubber donut-style giubos, the reinformed joints do not fall to pieces without fair warning. Obviously, if given the choice, a non-cracked unit is preferred over one with cracks. Looking "pristine" is a fair indication of condition, but it is no guarantee of longevity, considering all of the discussion regarding "German-made" rubber parts. Besides, enough missed shifts, abrupt clutch engagements and parking in gear on steep inclines can shorten the life of virtually any rubber joint. The same logic applies to improper handling and installation.

Since you plan to replace your giubo, try destroying it with long pry bars and you may be surprised to discover its true strength.

https://www.bimmerfest.com/forums/showthread.php?t=914069

Solid rubber "donut" style different than depicted in original post.

Last edited:

its installed backwards arrow goes to front

Not sure if serious...

Post #10

Yeah I know how the bolts & nuts need to be applied.

I’m showing the group that the pic is wrong , see below

I understand. The point of it being that you should be tightening the nut, not the bolt, and having the nut on the flange saves the rubber from getting stressed from the turning nut. That picture shows one of two things- Either the person who installed it didn't understand the concept I just mentioned, or they got everything in place and then realized that they forgot to put three bolts in the guibo before getting everything lined up and said F it.

reedreed

Well-Known Member

Using a long nosed manual driveshaft with a m5 guibo manual Install can result in a gap that gives a guibo a wavy distorted appearance. That wave is caused by the difference in thickness of a stock guibo (45mm) and an m5 guibo (35mm)

Inserting factory bmw head bolt washers into the gap solves the problem.

Also- instructions are explicit and nobody seems to read them.... never tighten the bolts! The nuts get tightened.

This preloads the guibo. Not good.

And finally - guibos have arrows for a reason. Put them on backwards and they crack and then come apart.

Catalog picture 26/03 - BMW 2,5 CS - 3,0 CSL (E9) - Propeller shaft | Wallothesch

1- if I install 35mm M5 guibo should I still keep the parts ## 2,3,4,5,6,7,8 on a diagram installed or m5 centering bushing 26 11 7 526 611 should be installed or nothing?

2- which bolt length needed 60, 62 or 70mm?

3- what's the ring #11 on a diagram for? And what's a bolt length used in original setup? (45 for guibo+ 10 for nut+ 12 for flange+ 2 for washer+ X for #2 ring= ???)

4- where exactly head bolts washers should be installed? Some pictures would be nice.

Thanks a lot!

I’m traveling to Texas for the annual 2002 drive with Terry - back in a week

I still have a few questions if possible:Catalog picture 26/03 - BMW 2,5 CS - 3,0 CSL (E9) - Propeller shaft | Wallothesch

www.wallothnesch.com

1- if I install 35mm M5 guibo should I still keep the parts ## 2,3,4,5,6,7,8 on a diagram installed or m5 centering bushing 26 11 7 526 611 should be installed or nothing?

2- which bolt length needed 60, 62 or 70mm?

3- what's the ring #11 on a diagram for? And what's a bolt length used in original setup? (45 for guibo+ 10 for nut+ 12 for flange+ 2 for washer+ X for #2 ring= ???)

4- where exactly head bolts washers should be installed? Some pictures would be nice.

Thanks a lot!

I used an M5 guibo for my 5-speed swap, here's a link to the parts I used, might be of some help, maybe.

Getting this 3.0CSi back on the road

Not much happening here, had our second child last spring so that put a serious halt to everything car related but I'm totally okay with that :) Excellent work as usual, Robert. Both in the bedroom and in the garage!

e9coupe.com

e9coupe.com

The bolts are installed wrong…the nuts have to be on the steel flange and the bolt heads on the rubber…