kkro

Well-Known Member

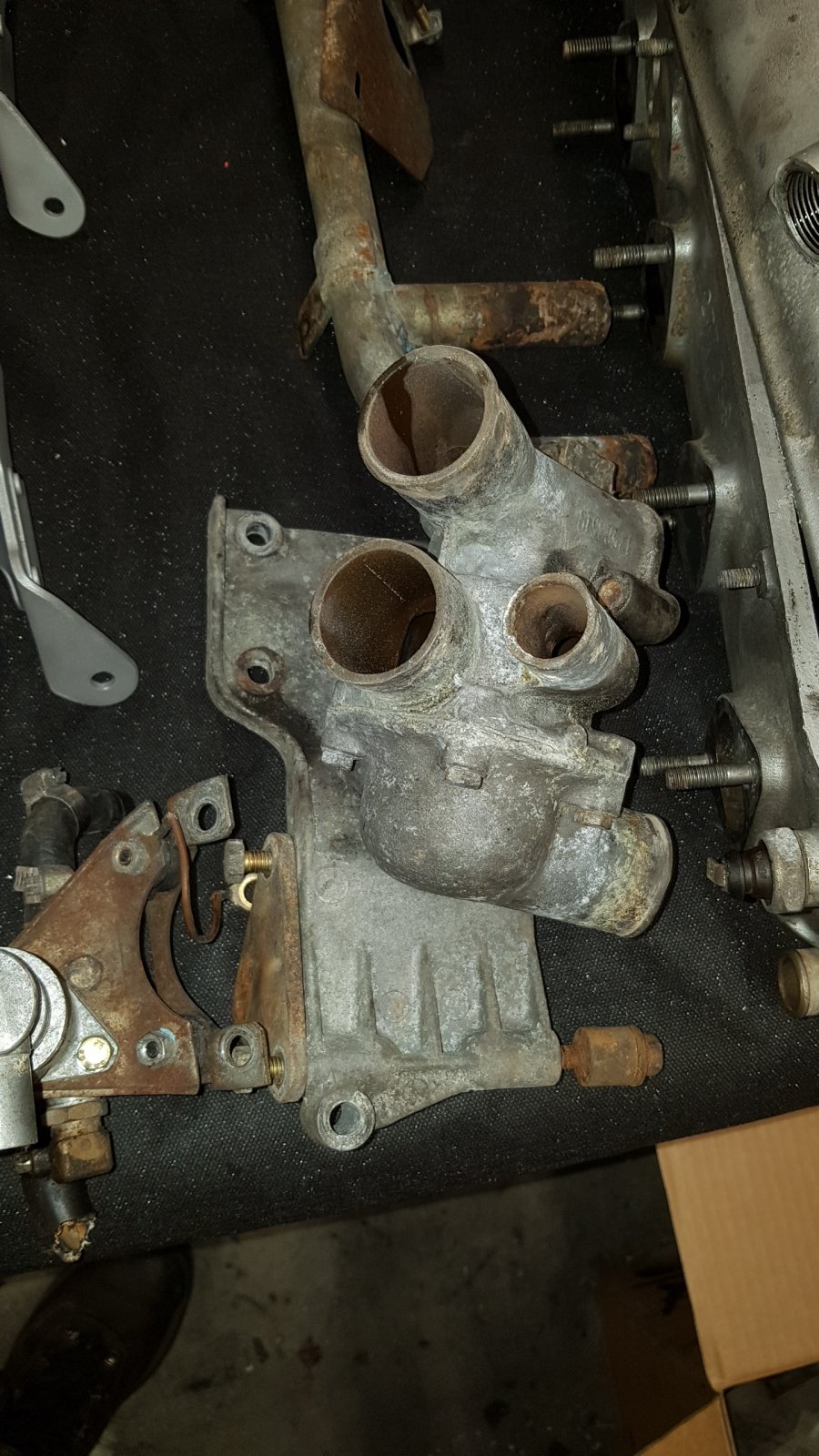

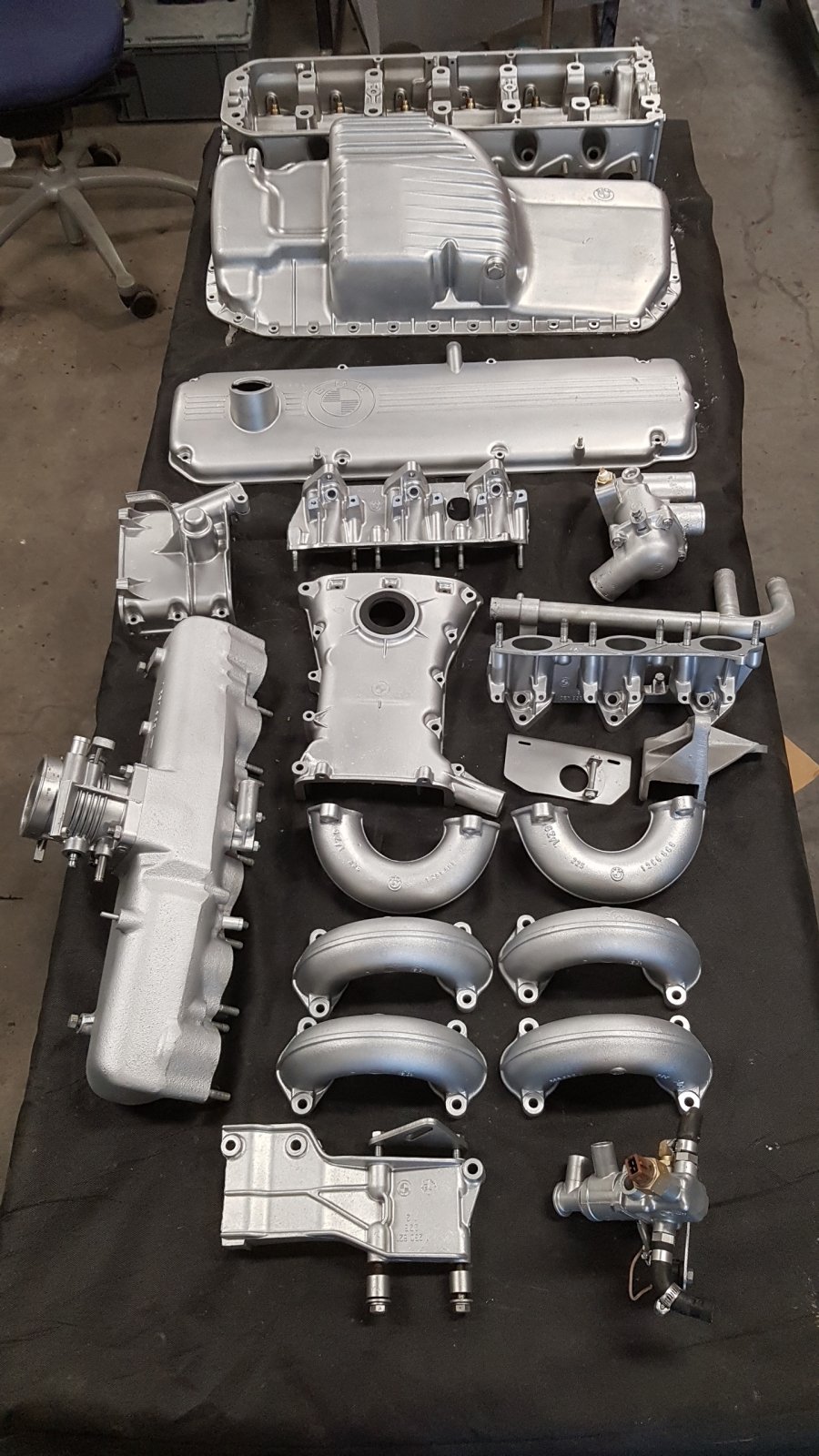

This post is a spin-off from my E3 refurbishment tread, but I thought it would be relevant also for E9 owners.

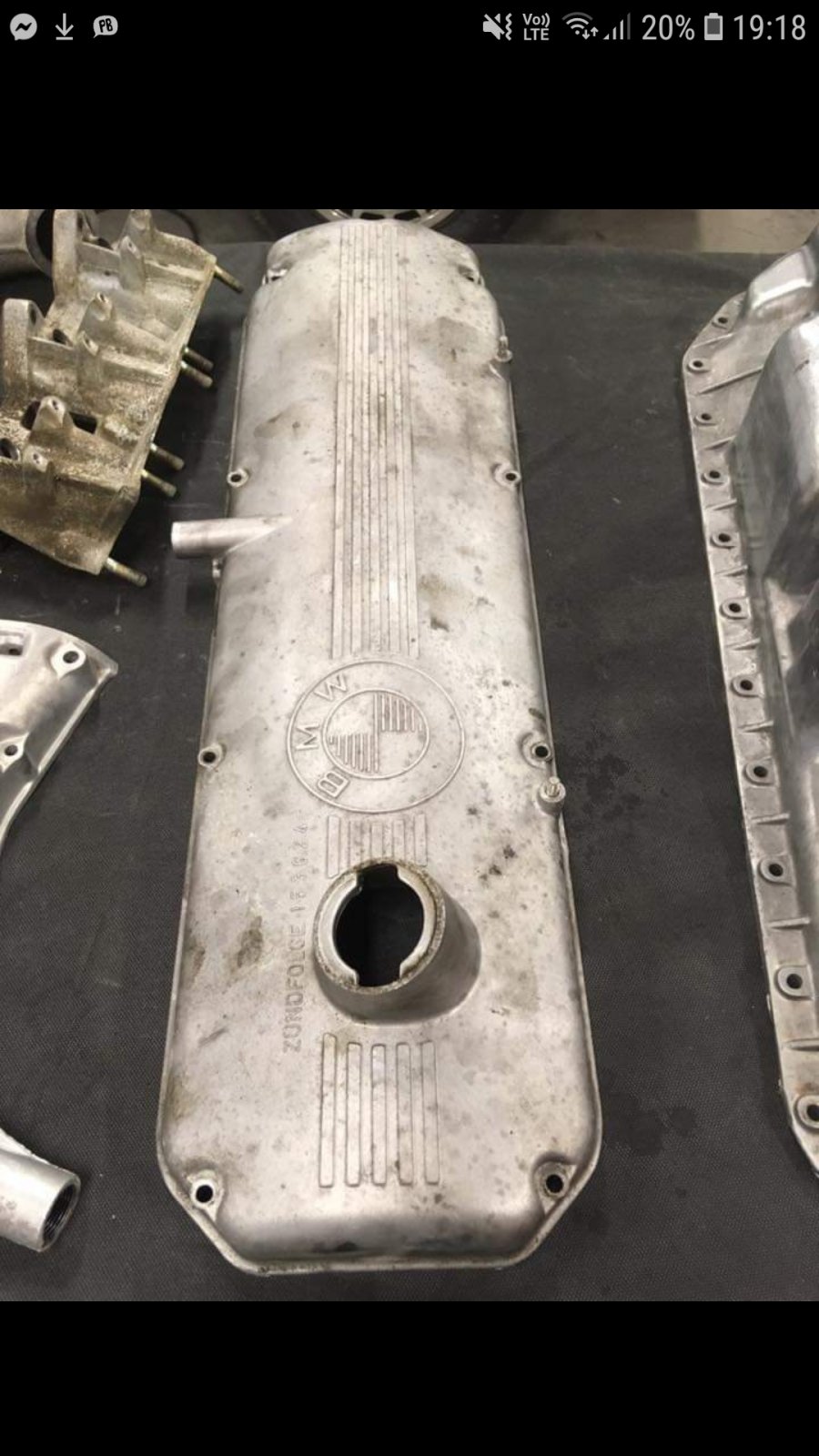

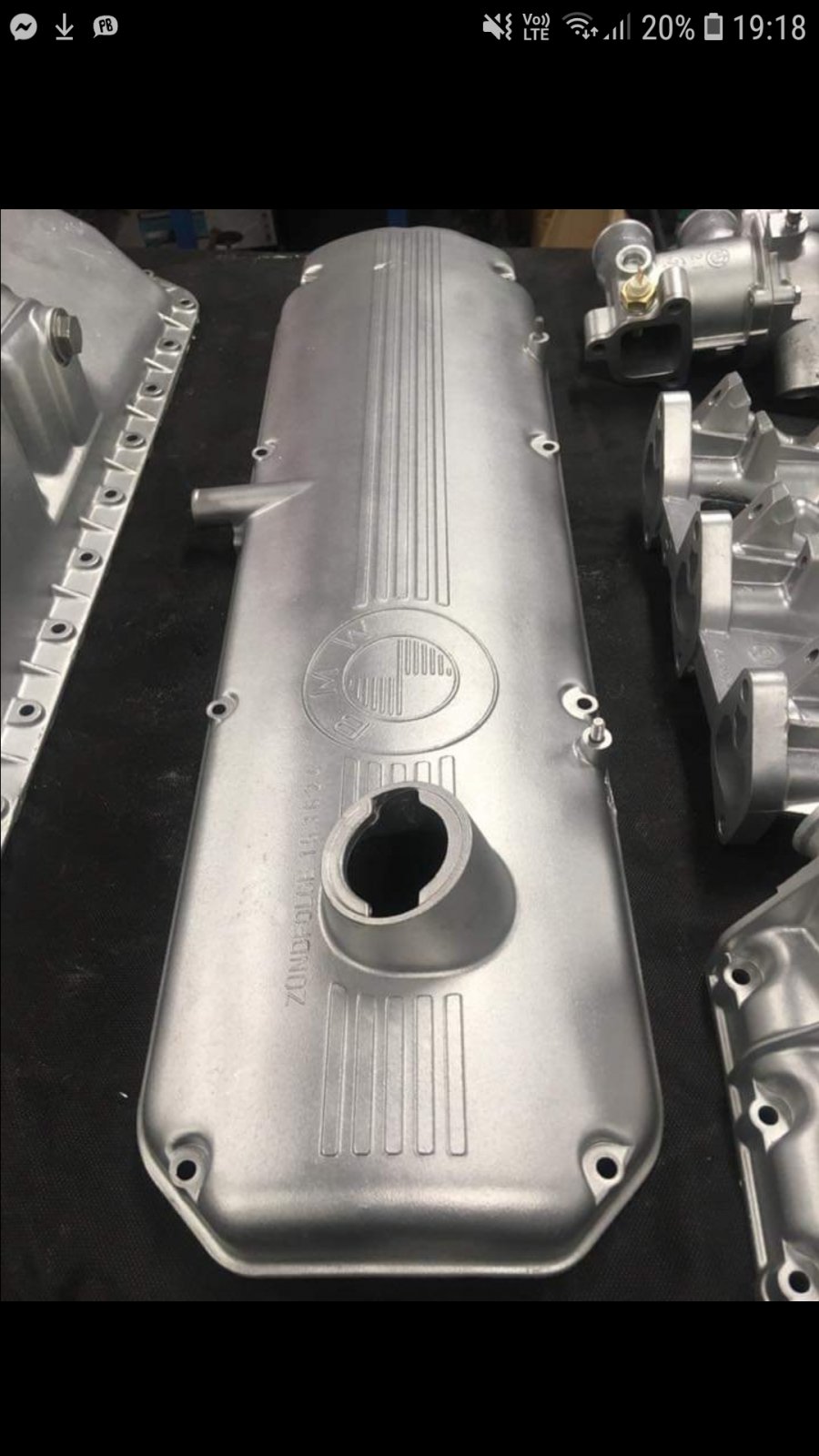

Yesterday I picked up the aluminum parts of my M30 from vapour honing. I think this is a great way of cleaning old corroded metal.

I paid around 300USD for cleaning these parts. It would have been fun to know how much it would have cost in the US? If anyone knows, please comment.

Some pictures. Before and after.

Does anyone have experience in how durable this finish will be over the years?

Yesterday I picked up the aluminum parts of my M30 from vapour honing. I think this is a great way of cleaning old corroded metal.

I paid around 300USD for cleaning these parts. It would have been fun to know how much it would have cost in the US? If anyone knows, please comment.

Some pictures. Before and after.

Does anyone have experience in how durable this finish will be over the years?