Are assembling a replacement head for our 2800cs. The rocker shafts are installed in the correct positions.

Upon installing rocker shafts and arms, we found the shafts are moving due to the spring tension on the rocker arms. This causes quite a misalignment of the rocker arm over the valve stem. See photos below. We are at a loss as to how to fix this. Not even sure new shafts would make any difference. Its the bolts. So what do we do?

The cutouts in the shafts where the head bolts go through are suppose to "lock" the shafts in place which by means of the increased diameter of the bolt right at the top under the hex head.

What we have found is with a new set of bolts supplied by W&N, the length of the larger diameter is too short, thus it barely engages the shaft cutout. This allows the shaft to move under the pressure of the springs on the rocker arms.

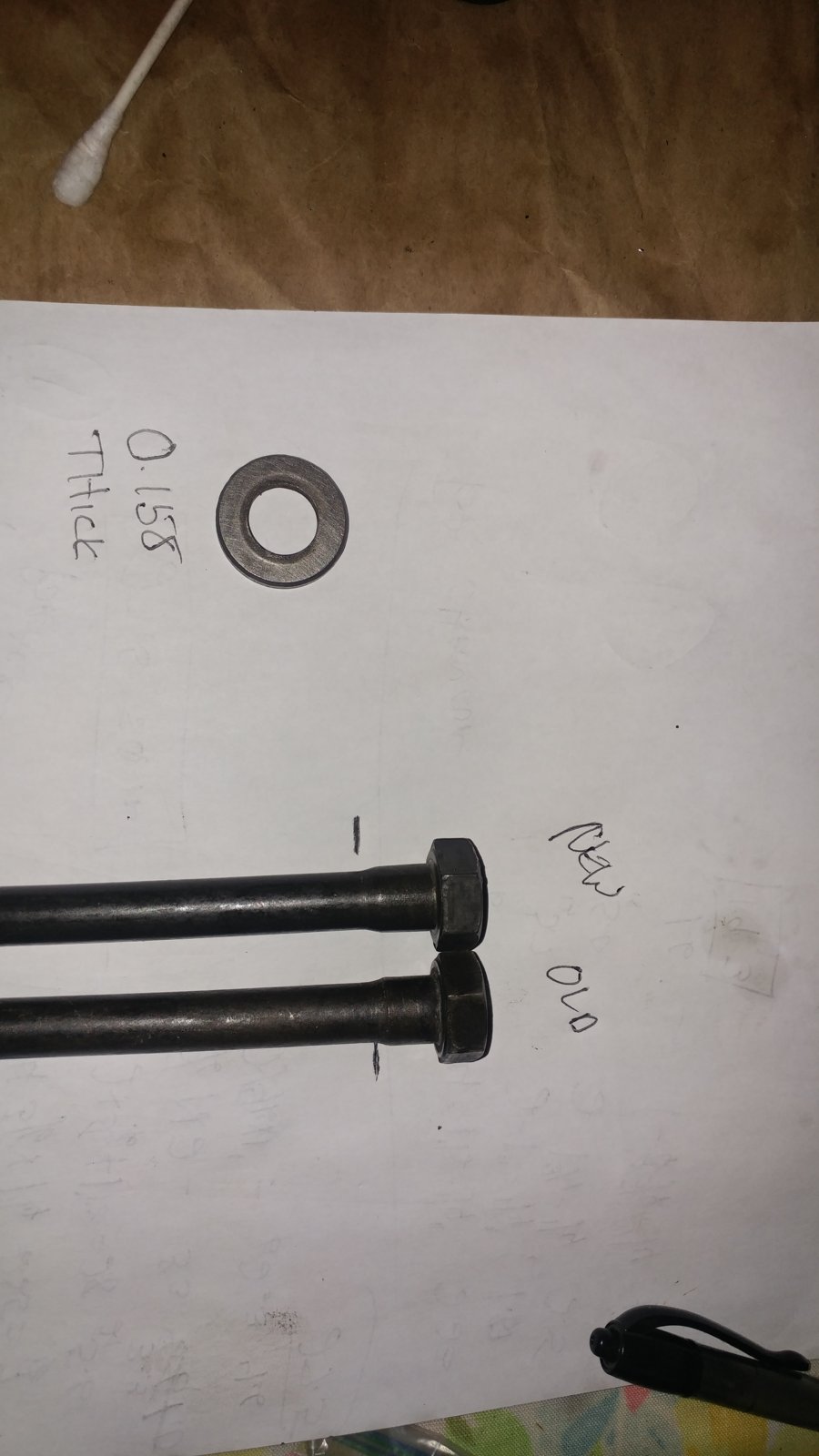

Here is a photo of a new bolt and an old removed bolt (which was even worse) showing the lenght of the larger diameter. The new bolt has a lenght of approximately 0.4" (10mm) while the older one has .360 (9mm). The washers are 0.158 thick (4mm).

The depth of the cutout locator in the head is approximately 5/16" (.312") or 8mm.

So adding the washer to the bolt and dropping in the head on the bench, the locating larger diameter of the head bolt only penetrates into the head by (10mm - 4mm washer thickness) or 6mm, barely engaging the rocker shaft cutouts, if at all. It looks like only the the taper from the larger diameter (~.485") down to the bolt diameter of .418" is engaging the shaft cutout. The threaded end is about .460"

We measured the amount of left to right movement by putting 4 bolts and washers on the front intake shaft and found it to be 3/16" (5mm). The photo shows a mark with the shaft at the left stop of the movement and then at the right stop of the movement, showing the total lateral movement.

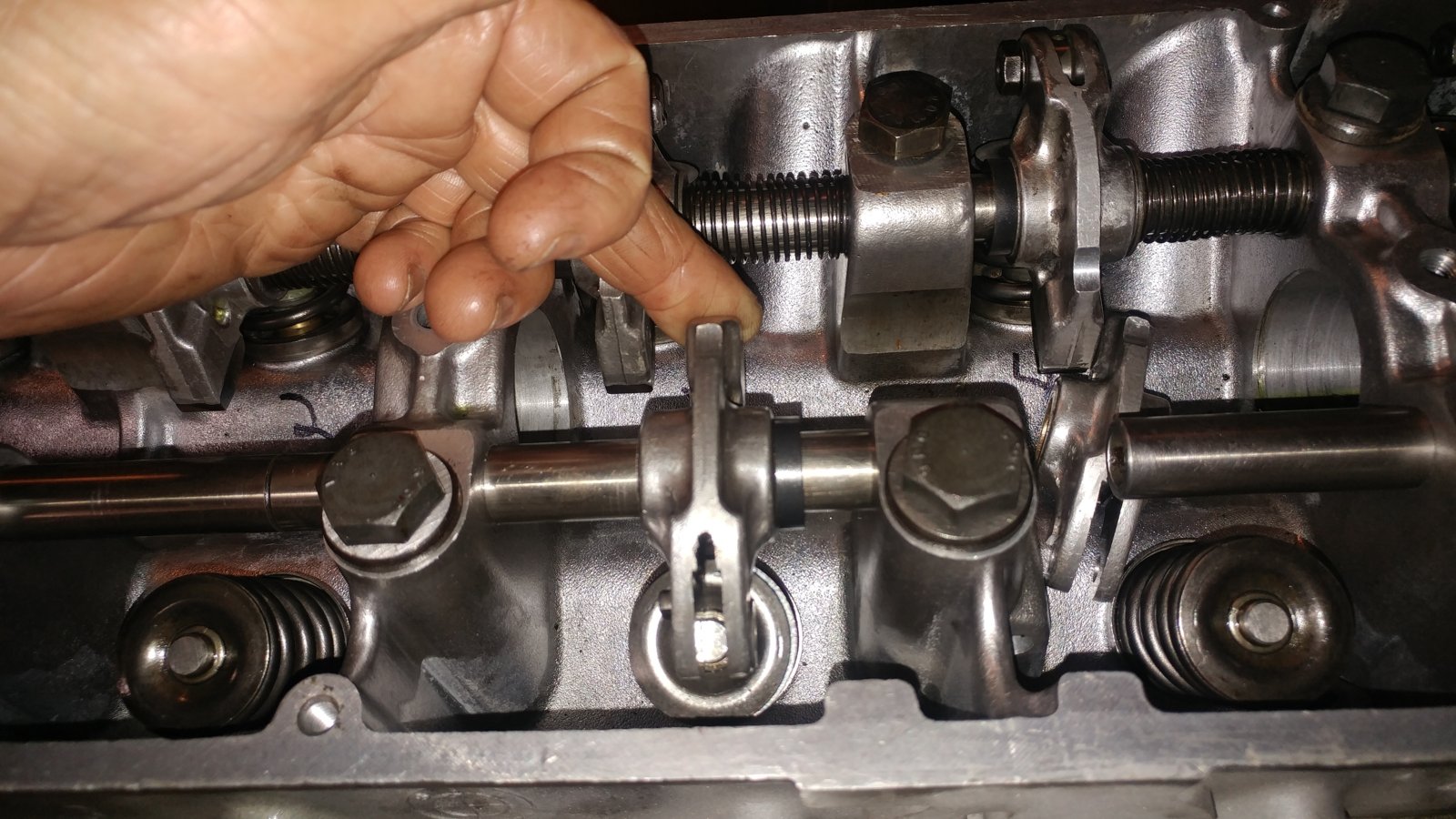

Here is a shot of the a rocker arm installed missing the eccentric for clarity, showing how far off the rocker arms will be, once the springs are installed, which we had done and that's how we found the issue. It actually worse than the photo shows. We did center the the shaft by inserting a rod solid rod of similar diameter of the the head bolt to center the shaft (as shown in the above photo) and by doing so, the rocker arms line up right over the top of the valve stem.

The issue now is how to fix the problem? Here is a thread on another forum that explains the issue maybe better than us.

This article seems to indicate that BMW changed the design of the head bolts and the length of the wide part was reduced. Does anyone have a photo of an original bolt and measure that depth?

Of course the reason the shafts move in the head is that the wide part of installed head bolts is too short to reach the cut-outs in the shafts. Without any positive locking, the shafts just moved backwards under the pressure from the springs.

The fix?

On the intake side, some have put a spacer in the back of the head between the end of the shaft and the backing plate. In fact we found a nut inside our old head upon disassembly acting as a spacer. Now we know why it was there.

On the exhaust side the problem is the springs now are pushing the shafts forward. And there is nothing to block it like the intake side which gets pushed towards the back. Here is out situation. The shaft is sticking out of the head. All the exhaust rockers are misaligned over the stems.

One solution was someone in the above thread actually had 4 special bolts made with longer shanks to lock in the shafts. They are installed where there is no oil flow, at the 4 places where the lubrication spray rod gets installed.

Upon installing rocker shafts and arms, we found the shafts are moving due to the spring tension on the rocker arms. This causes quite a misalignment of the rocker arm over the valve stem. See photos below. We are at a loss as to how to fix this. Not even sure new shafts would make any difference. Its the bolts. So what do we do?

The cutouts in the shafts where the head bolts go through are suppose to "lock" the shafts in place which by means of the increased diameter of the bolt right at the top under the hex head.

What we have found is with a new set of bolts supplied by W&N, the length of the larger diameter is too short, thus it barely engages the shaft cutout. This allows the shaft to move under the pressure of the springs on the rocker arms.

Here is a photo of a new bolt and an old removed bolt (which was even worse) showing the lenght of the larger diameter. The new bolt has a lenght of approximately 0.4" (10mm) while the older one has .360 (9mm). The washers are 0.158 thick (4mm).

The depth of the cutout locator in the head is approximately 5/16" (.312") or 8mm.

So adding the washer to the bolt and dropping in the head on the bench, the locating larger diameter of the head bolt only penetrates into the head by (10mm - 4mm washer thickness) or 6mm, barely engaging the rocker shaft cutouts, if at all. It looks like only the the taper from the larger diameter (~.485") down to the bolt diameter of .418" is engaging the shaft cutout. The threaded end is about .460"

We measured the amount of left to right movement by putting 4 bolts and washers on the front intake shaft and found it to be 3/16" (5mm). The photo shows a mark with the shaft at the left stop of the movement and then at the right stop of the movement, showing the total lateral movement.

Here is a shot of the a rocker arm installed missing the eccentric for clarity, showing how far off the rocker arms will be, once the springs are installed, which we had done and that's how we found the issue. It actually worse than the photo shows. We did center the the shaft by inserting a rod solid rod of similar diameter of the the head bolt to center the shaft (as shown in the above photo) and by doing so, the rocker arms line up right over the top of the valve stem.

The issue now is how to fix the problem? Here is a thread on another forum that explains the issue maybe better than us.

This article seems to indicate that BMW changed the design of the head bolts and the length of the wide part was reduced. Does anyone have a photo of an original bolt and measure that depth?

Of course the reason the shafts move in the head is that the wide part of installed head bolts is too short to reach the cut-outs in the shafts. Without any positive locking, the shafts just moved backwards under the pressure from the springs.

The fix?

On the intake side, some have put a spacer in the back of the head between the end of the shaft and the backing plate. In fact we found a nut inside our old head upon disassembly acting as a spacer. Now we know why it was there.

On the exhaust side the problem is the springs now are pushing the shafts forward. And there is nothing to block it like the intake side which gets pushed towards the back. Here is out situation. The shaft is sticking out of the head. All the exhaust rockers are misaligned over the stems.

One solution was someone in the above thread actually had 4 special bolts made with longer shanks to lock in the shafts. They are installed where there is no oil flow, at the 4 places where the lubrication spray rod gets installed.