_in progress of compiling thread_

On my car the interior armrests on the doors show quite uneven gaps to the door panel, even though the screws are really tightened. Plus when you pull the door, you feel a lot of flex in the armrests. This always buggered me.

My car also came equipped with the chrome bling-bling spacer/bezels when I bought the car, bit these simply break due to the stress of the deformation.

Here's a pic showing how wonky the alignment is, and the resulting cracks and deformation of the chrome bezel (which is actually an e3 part):

Today i was hanging my doors back in to be able to weld in the 4 patch panels from Walloth on the rear valance and the front fenders; and i needed the doors to get good panel gaps.

Upon disassembly of the doors I saw what is causing this wobbly armrest: it's the result of a bad design from BMW, combined with (my?) overtightening of the armrest screws.

Here a brief explanation of what happens, and how to correct it.

The armrests are screwed to the doorframe with 4 beefy sheet metal screws. They are inserted through the armrest from the underside to hide them, and therefor go into the frame of the door under an angle.

The brown armrests themselves have a metal bracket inside, probably running the length of the armrest. That bracket also supports the heads of each screw. The metal brackets in my armrests have deformed around the screw locations, allowing a gap to develop at the top of the armrest, and give the armrest a loose feeling.

(curious to know if other experience the same; i expected the armrest to behave more rigid)

When looking at my armrest; it was noticeable that the metal bracket was deformed, especially the area around the screw head. The bracket should be flat, but they are bulging, bending outwards. In the pic below they can be seen protruding from the flat foam surface, where they should be flush. When under tension by the screw, they deform and stick out by about 5 mm (1/5th of an inch)

This deformation is due to the doorframe having not a nice flat surface for the metal bracket to push against. The metal frame of the door, where the screws attach, has a weld on metal plate with for a self tapping screw. That plate is angled downwards to allow the screw to go in at 90 degree. It is recessed. As a consequence of that angled section on the door panel, there is only a minimal surface of the door frame around the screw hole to support (“push back”) on the armrest.

As a consequence, the metal bracket deforms when you tighten the screws; the bracket simply sinks in to open space between the bracket and the doorframe.

Meanwhile it also deforms your door panels' fiber board and vinyl. And for those that use the E3 Chrome plates; those break as well as a result.

The images below show where the gap is that exist between the armrest and the door panel. It is looking upwards, from under the armrest. Just above the screw the armrest is pulled up to the door panel. Where my finger is, is a large, empty void. If you lean on the armrest, there is no supporting surface to keep it from bending down.

Herewith 2 solutions to prevent this effect from happening, and likely improve the rigidity of the armrest. (I haven't tried it yet / will update when finished):

- Quick and easy: add a steel plate on top of the doorframe around each screw hole, or one single plate of roughly the size of the whole armrest. Downside is that it adds thickness which may show or interfere with door pull opener and /or the window winder arm. I do not have pics of this solution yet- update will follow

- insert pic-

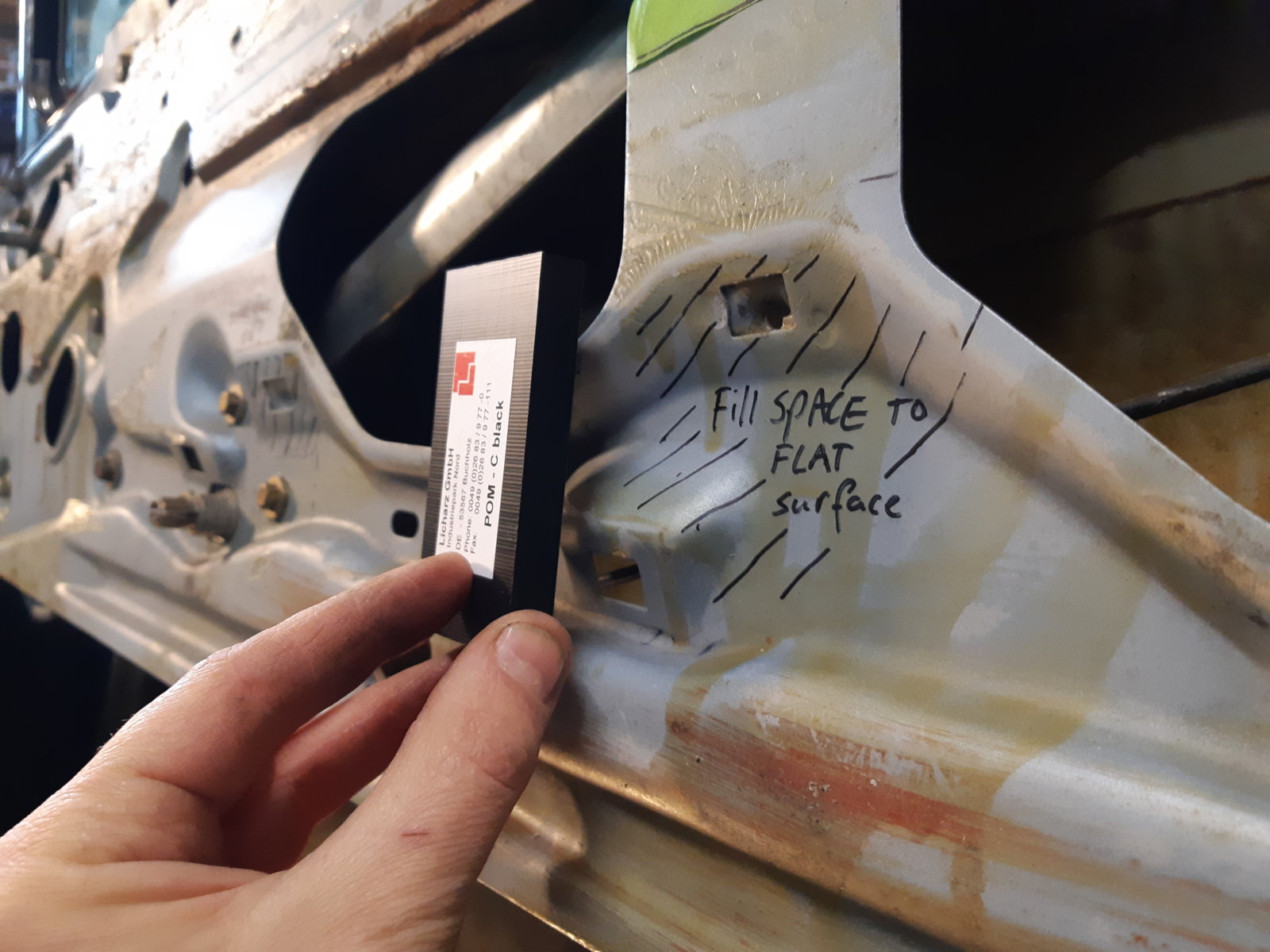

- a bit more work is to create individual blocks to fill the missing volume. Wood, solid plastic, alu, steel; it will all work, but the shape is rather complex so some accurate measuring is in order. But in solid plastic, with a simple saw or Dremel you’ll be successful in 30 minutes per block=per screw.

the attached 3 images show roughly the 3 spaces around the 3 screw points that I'd like to fill in order to create that flat surface for the armrest to push on.

Use the black plastic block (reshaped) to fill the void it now creates;

Use the black plastic block (reshaped) to fill the void it now creates;

And on the other 2 screw points;

I do not have pics of this solution in it's final state yet- update will follow, perhaps in about 2-3 years

Curious to learn if others also feel that their armrest is 'weak'

-insert link to thread about the small bracket to reinforce the upper mounting point -

On my car the interior armrests on the doors show quite uneven gaps to the door panel, even though the screws are really tightened. Plus when you pull the door, you feel a lot of flex in the armrests. This always buggered me.

My car also came equipped with the chrome bling-bling spacer/bezels when I bought the car, bit these simply break due to the stress of the deformation.

Here's a pic showing how wonky the alignment is, and the resulting cracks and deformation of the chrome bezel (which is actually an e3 part):

Today i was hanging my doors back in to be able to weld in the 4 patch panels from Walloth on the rear valance and the front fenders; and i needed the doors to get good panel gaps.

Upon disassembly of the doors I saw what is causing this wobbly armrest: it's the result of a bad design from BMW, combined with (my?) overtightening of the armrest screws.

Here a brief explanation of what happens, and how to correct it.

The armrests are screwed to the doorframe with 4 beefy sheet metal screws. They are inserted through the armrest from the underside to hide them, and therefor go into the frame of the door under an angle.

The brown armrests themselves have a metal bracket inside, probably running the length of the armrest. That bracket also supports the heads of each screw. The metal brackets in my armrests have deformed around the screw locations, allowing a gap to develop at the top of the armrest, and give the armrest a loose feeling.

(curious to know if other experience the same; i expected the armrest to behave more rigid)

When looking at my armrest; it was noticeable that the metal bracket was deformed, especially the area around the screw head. The bracket should be flat, but they are bulging, bending outwards. In the pic below they can be seen protruding from the flat foam surface, where they should be flush. When under tension by the screw, they deform and stick out by about 5 mm (1/5th of an inch)

This deformation is due to the doorframe having not a nice flat surface for the metal bracket to push against. The metal frame of the door, where the screws attach, has a weld on metal plate with for a self tapping screw. That plate is angled downwards to allow the screw to go in at 90 degree. It is recessed. As a consequence of that angled section on the door panel, there is only a minimal surface of the door frame around the screw hole to support (“push back”) on the armrest.

As a consequence, the metal bracket deforms when you tighten the screws; the bracket simply sinks in to open space between the bracket and the doorframe.

Meanwhile it also deforms your door panels' fiber board and vinyl. And for those that use the E3 Chrome plates; those break as well as a result.

The images below show where the gap is that exist between the armrest and the door panel. It is looking upwards, from under the armrest. Just above the screw the armrest is pulled up to the door panel. Where my finger is, is a large, empty void. If you lean on the armrest, there is no supporting surface to keep it from bending down.

Herewith 2 solutions to prevent this effect from happening, and likely improve the rigidity of the armrest. (I haven't tried it yet / will update when finished):

- Quick and easy: add a steel plate on top of the doorframe around each screw hole, or one single plate of roughly the size of the whole armrest. Downside is that it adds thickness which may show or interfere with door pull opener and /or the window winder arm. I do not have pics of this solution yet- update will follow

- insert pic-

- a bit more work is to create individual blocks to fill the missing volume. Wood, solid plastic, alu, steel; it will all work, but the shape is rather complex so some accurate measuring is in order. But in solid plastic, with a simple saw or Dremel you’ll be successful in 30 minutes per block=per screw.

the attached 3 images show roughly the 3 spaces around the 3 screw points that I'd like to fill in order to create that flat surface for the armrest to push on.

And on the other 2 screw points;

I do not have pics of this solution in it's final state yet- update will follow, perhaps in about 2-3 years

Curious to learn if others also feel that their armrest is 'weak'

-insert link to thread about the small bracket to reinforce the upper mounting point -

Last edited: